THE Department of Trade and Industry (DTI) is eyeing to “enhance” the Philippines’s participation in the global value chain of electronics particularly in the areas of research and development and production of wafer technology, DTI Assistant Secretary for International Trade Policy and Trade Negotiation Allan B. Gepty told a forum last Saturday.

Describing electronic products as the “niche” of the Philippines, Gepty said the country’s participation in the global value chain is currently in the area of assembly and testing.

Hence, moving forward, he said “there are two aspects that we are targeting—research and development and production of wafer technology.”

Gepty underscored the importance of the country capturing these “additional stages” in the global value chain of electronics as the Philippines has already established a niche in the electronics industry.

Moreover, the Trade official noted the Trade department is eyeing to develop the country’s manufacture and assembly of final products.

“Kasi pag final product siyempre ‘yung value mas mataas,” Gepty said. [Of course, the value of the final product is higher.]

At a forum organized by the Board of Investments (BOI) two weeks ago, Semiconductor and Electronics Industries in the Philippines Foundation Inc. (SEIPI) President Danilo C. Lachica said Seipi is hoping to partner with American companies to build the semiconductor supply chain in the Philippines.

Lachica said the organization of foreign and Filipino electronics companies in the Philippines would have to tap US semiconductor firms because “it’s expensive to build the wafer fab.”

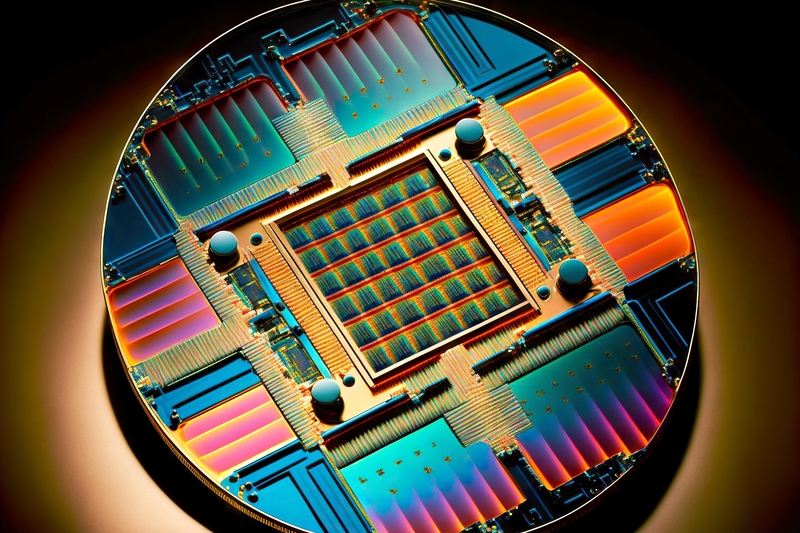

As defined by Analog Devices Inc., an American multinational semiconductor firm, wafer fab is a semiconductor processing facility which turns wafers into integrated circuits.

Lachica explained the semiconductor supply chain includes the integrated circuit (IC) design, wafer fab and assembly, test and packaging.

The Seipi chief emphasized that the wafer fab is the “big gap in between,” albeit having the assembly, test and packaging and the IC design.

Lachica illustrated the current process, saying that what they do today is to “send the tapes or Gerber files to a wafer fab specifically to TSMC [Taiwan Semiconductor Manufacturing Co.].”

However, he mentioned the challenges that come with this, such as cost, lead time and “the more concerning thing,” Lachica said, would be the protection of the (intellectual property) IP.

“Of course when you send the chips there then you expose the secrets to the world so what we want to propose is to…with the help of the government, DTI, Department of Science and Technology [DOST] and the other possible sources is to build a large scale wafer fab in the Philippines and hopefully some of the Chips fund would be carved out for that,” the Seipi chief said two weeks ago.

Meanwhile, Lachica said “there is news that the [Creating Helpful Incentives to Produce Semiconductors and Science Act of 2022] Chips Act will probably allocate some funds for the Philippines.”